As CEO of the Victoria Hand Project, a charity spun out of the University of Victoria in British Columbia, Michael Peirone is a jack of all trades: engineering, operations, IP, business strategy, fundraising and biological systems. He began working with the project in 2014 while completing his degree in biomedical engineering at the university. During two internships with the project, he expanded its operations to Nepal and after graduating, he joined the project full-time as a biomedical system designer before serving as COO where he established four new international clinics. He was named CEO in 2021. In this interview with BioTuesdays, Mr. Peirone discusses the global need for prosthetic hands and upper limbs in the developing world, and how Victoria Hand fits and delivers its products.

Let’s begin with a brief history of Victoria Hand Project.

We began as a research project in the mechanical engineering lab of Prof. Nick Dechev, Ph.D., who designed a functional prosthetic hand more than a decade ago but he deemed it too expensive to feasibly manufacture. In 2012, a student suggested 3D printing the prosthetic hand just as the industry was coming into its own. To test the concept, Dr. Dechev received a research grant to study range of motion of 3D printed hands in Guatemala. Study participants were encouraged to keep their new prosthetics and Dr. Dechev decided to start a non-profit charity, which became Victoria Hand Project. He remains chairman and chief technology officer of the program.

How has the concept developed?

Our focus is to provide low-cost customized prosthetic care to people in resource poor countries around the world as well as low income communities in the U.S. and Canada where people are unable to pay out-of-pocket costs for a prosthetic device. Internationally, we now operate in Haiti, Guatemala, Ecuador, Uganda, Kenya, Cambodia, Nepal, Pakistan and Egypt, with plans to expand to Ukraine this summer. We partner with medical professionals in-country, training them how to create prosthetic devices in their own clinics, which lays the groundwork for sustainable, on-going care, and supports our model of transferring knowledge and technology to the communities we work in.

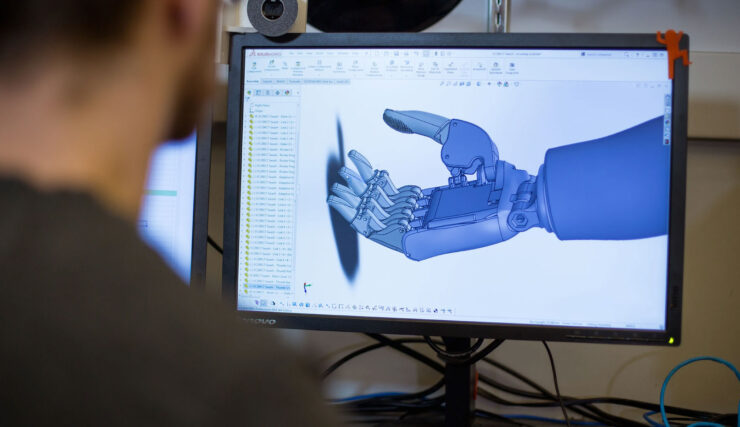

What role do your clinical partners provide?

We do the engineering here at our lab space at the University of Victoria, where we design small and large hands, design the work flow, and software solutions, and our clinical partners perform the actual 3D printing and scanning to produce prosthetic hands in their own clinics. Many of our partners have never used a 3D printer, so we provide the education on how to use them, so they can produce the finished prosthetic. And if 3D printing doesn’t exist in-country, we’ll fund raise to provide a printer to a partner.

How do you select people to receive a prosthetic?

This is done primarily by our clinicians in-country who assess prospective patients to see if their anatomy is correct for a prosthetic device. They take measurements of affected and unaffected limbs as well as a plaster impression of the arm that is eventually modified into a shell and 3D scanned to create a custom socket. Currently, we are unable to help people with missing fingers or parts of a hand. However, we are looking to help these people when we are able to bring in more engineers and designers.

What other components do you 3D print?

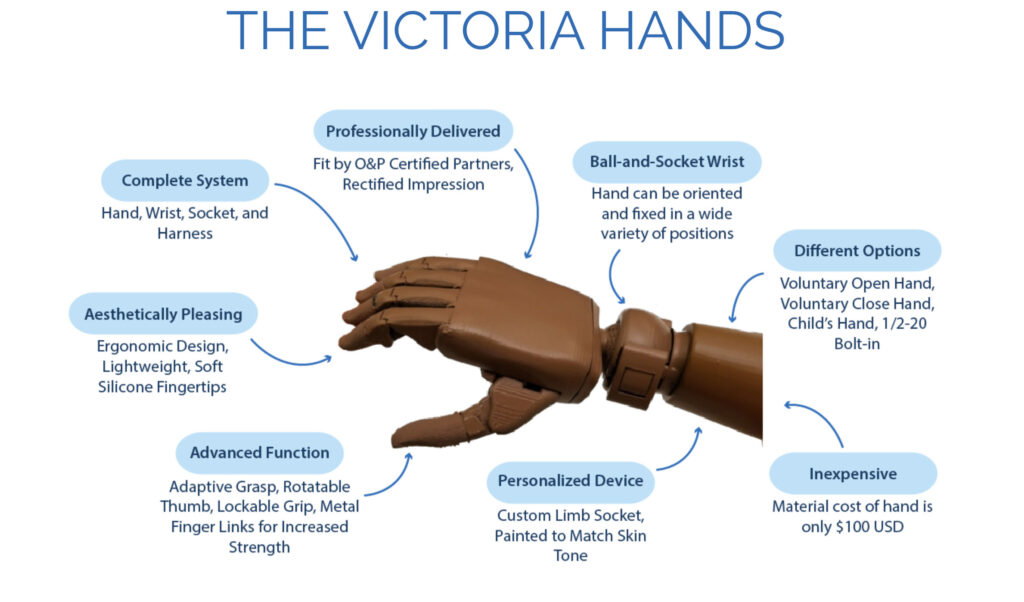

The wrist and shoulder harness system are both body-powered, with no electronics in order to keep costs down. There’s also the limb socket. By 3D scanning, we capture the shape of someone’s limb that fits into the stock and cut it out so we are left with a cavity in the socket that is the exact size of someone’s limb. This gives the user a safe and comfortable fit.

What’s the global need for upper prosthetic limbs?

The WHO estimates that of the three million upper-limb amputees worldwide, of which 80% live in developing countries and only 5% of them have access to prosthetic care. Developing countries often lack the infrastructure to manufacture prosthetics and they have few trained professionals to work with amputees. In many developing countries, there is also a stigma or superstition associated with limb loss that prevents amputees from returning to society.

What does a Victoria Hand cost?

Each 3D hand costs $100 in materials to create and each $300 of fund raising fits one amputee with a hand, including payment for the prosthetist and technician.

How may people have received one?

More than 250 patients worldwide have been fitted with a Victoria Hand to date but the positive impact extends to more than 500 amputees, caretakers, and families. As a charity, we depend on public and private sector grants to set up partner clinics, who are paid for each 3D device they install, which helps support their costs.

If Victoria Hand was a business, could you generate a profit?

We are beginning to look into the potential of a for-profit branch that would provide care to people who have the means to pay the out-of-pocket expense for prosthetic care. This would further support our charity endeavors as well.

How does Victoria Hand compare to traditional prosthetics?

Our devices are very functional. Traditional hook-pincer prosthetics, for example, are limited to opening and closing, while Victoria Hand consists of a thumb and four fingers that is more natural looking and can grasp objects very easily. We also match the color of the prosthetic to skin tones of recipients. When a traditional device closes and the first finger makes contact with an object, the other fingers stop closing. That compares to a Victoria Hand where the fingers continue to close to an extent, making for a more natural grasp. Bioelectric hands can cost in the area of $10,000, which is out of reach for the communities we work in.

Editor’s note: Donations can be made through the website, victoriahandproject.com

• • • • •

To connect with Victoria Hand Project or any of the other companies featured on BioTuesdays, send us an email at [email protected].