Closely-held Axolotl Biosciences is developing a bioink specifically formulated for the bioprinting of neural tissue, for biotechnology and pharmaceutical companies to use for research and development purposes.

“Last fall we received a lot of interest from researchers who wanted to buy our bioink, so we decided to form a company,” Axolotl’s CEO, Stephanie Willerth, says in an interview with BioTuesdays. “Shortly after winning the University of Victoria’s internal entrepreneurship competition, we joined their incubator and incorporated in the midst of the pandemic, in March 2020.”

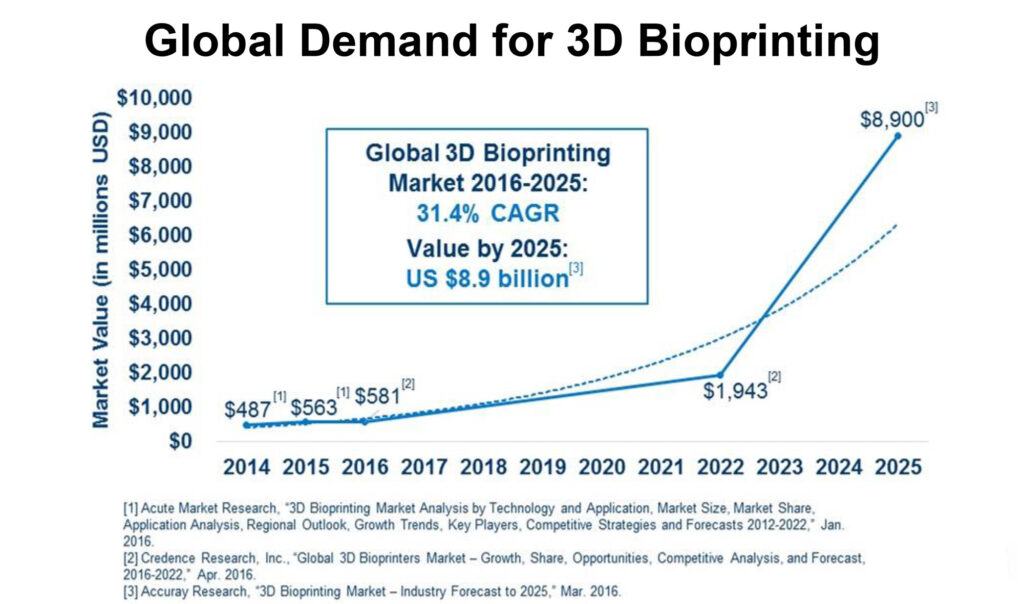

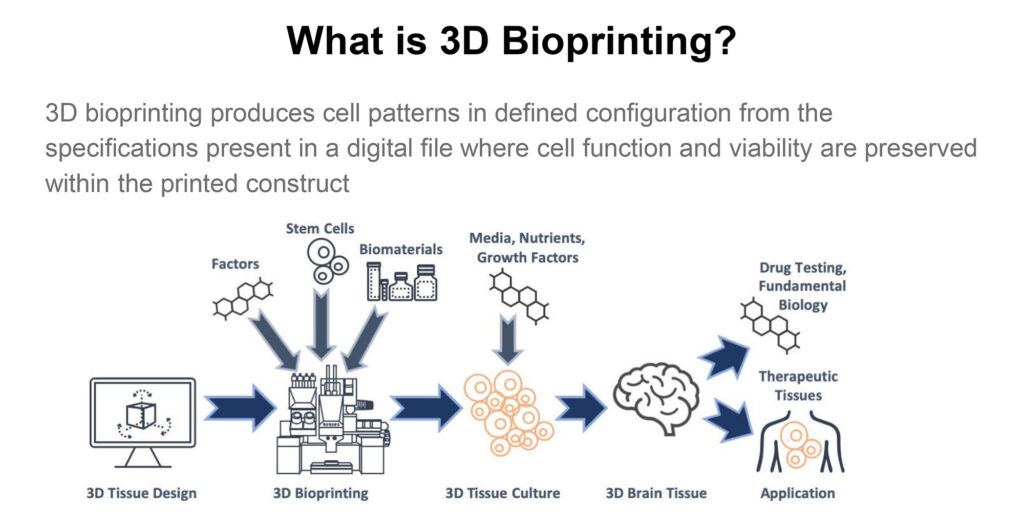

Compared with conventional 3D printing, where a plastic filament gets extruded according to a design file, bioprinting uses specialized cell-based material and the design file dictates the desired tissue shape. Dr. Willerth says that while bioprinting is still a relatively new field, the market is growing.

“There are a lot of bioprinters on the market, but what is really lacking is a good bioink for neural tissue,” she says. “If you go through all the work to grow the cells and lose half of the cells when printing, that’s not desirable.”

To prepare for bioprinting, pluripotent stem cells – which have the potential to become any tissue in the body – are differentiated into neural tissue over a period of one-to-two months.

Generally, current bioinks offer a straightforward bioprinting medium, but they are not ideal for sustaining living cells. “We have used stem cells to make brain organoids in a petri dish in our lab. The challenge though, is that stem cells are notoriously hard to print, and they often die when printed with other bioinks, such that only about one-in-four cells comprising the organoid are functional.”

Moreover, Dr. Willerth points out that it is very difficult to create neural tissue that behaves in the same manner as actual brain tissue.

During her doctorate, Dr. Willerth studied fibrin as a base material, which was so good at supporting cell growth that she used it to develop printable formulations using different types of microspheres.

“Our ink supports both cell survival and function,” she contends. “Cells printed using our bioink are viable and function well, and you can observe that they have electrical function and respond to neurotransmitters.”

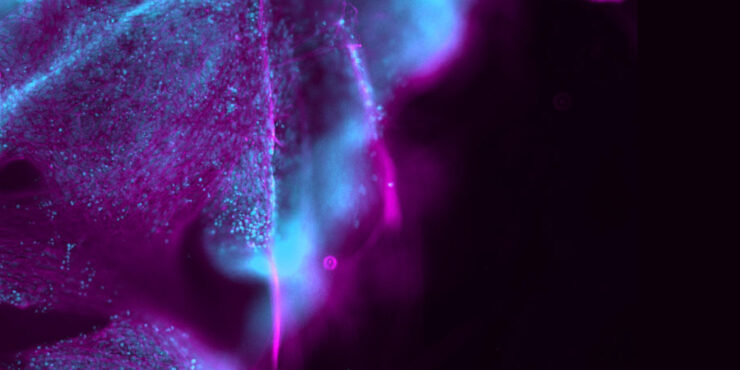

Axolotl has optimized its inks and printout formulations, and has printed a number of neural cell types using the multiple bioprinters at Dr. Willerth’s lab.

“Our inks can create reproducible constructs that can last for more than a month, which we can use to make functional neural tissue. We are able to print a lot of tissue, and have printed 150 miniature hearts in a single day.”

The company has advanced two bioink formulations – one for printing brain tissue and one for printing spinal cord tissue – that Dr. Willerth believes will be Axolotl’s next two products. “Our bioink production costs and price are in line with currently available bioinks,” she points out.

Axolotl has been in discussions with multiple academic institutions and biotechnology companies who are interested in using the company’s bioink for research and development purposes. Dr. Willerth says that the demand for 3D printed neural tissue is being driven by lack of tools available to predict how drug candidates will act on these types of tissue.

“Neurodegenerative disorders such a Parkinson’s disease and Alzheimer’s disease are still in need of a cure, and part of the reason why it is so hard to get drugs for these diseases approved is that there are limited predictive tools. The ability to bioprint humanized tissue is very attractive to the pharma industry,” she says.

Axolotl has sent its beta bioink version to collaborators at the University of British Columbia and the University of Texas for testing. Dr. Haakon Nygaard, Fipke professor in Alzheimer’s research at the UBC, is interested in Axolotl’s bioink for the printing of brain tissue using blood cells from Alzheimer’s disease patients.

“These cells are reprogrammed back into induced pluripotent stem cells, and if you differentiate those into neural tissue, you can track biomarker outputs such as beta amyloid and tau, whose increased expression is associated with Alzheimer’s disease,” Dr. Willerth explains.

Dr. Nygaard is planning to use this neural tissue to test drug candidates from a library of compounds deemed safe in humans but without a specific indication to evaluate how they impact disease biomarkers. “Should any of these drugs seem promising, Dr. Nygaard could prescribe these drugs to his patients on an off-label basis,” she contends.

Axolotl plans to send its beta product for testing to various bioprinting companies, including Cellink and Brinter, in hopes they will eventually distribute the company’s bioink.

The company aims to secure partnerships for the distribution of its bioinks this fall. While Axolotl plans to focus on getting its first two bioink products to market in the near-term, it plans to develop tissue models on which companies may test their drug candidates.

Dr. Willerth adds that Axolotl has been talking to Health Canada regarding the potential to approve certain 3D printed humanized tissue models for drug testing, as part of a preclinical toolkit.

“Bioprinting is a sustainable way to test drugs on living tissue, and while it may not get a drug candidate into the clinic, it could certainly strengthen the case.”

• • • • •

To connect with Axolotl Biosciences or any of the other companies featured on BioTuesdays, send us an email at [email protected].