As a co-founder and CEO of closely-held Cellares, which is pioneering an automated approach to cell therapy manufacturing, Fabian Gerlinghaus, an aerospace engineer by training, made the switch to biotech eight years ago. He has established a track record of assembling top-performing teams to drive novel bioprocessing technologies from lab bench to commercial readiness. Prior to Cellares, Mr. Gerlinghaus served as chief innovation officer at Synthego, where he co-invented the company’s proprietary RNA synthesizer technology and took this device from whiteboard sketch to a production-ready instrument within two years, enabling the company to be the first to market with its CRISPR/Cas9 product portfolio. In this interview with BioTuesdays, Mr. Gerlinghaus discusses the challenges in cell therapy manufacturing and how Cellares’ Cell Shuttle is addressing those issues.

Let’s start with a brief history of Cellares.

We started the company in 2019 and have raised more than $100-million in less than two years. We grew the company from the three founders, to a team of more than 50 employees and expect that to grow to more than 150 by the end of 2022. While we are still in the development phase with the Cell Shuttle, we are moving at epic speed and expect to be on the market in late 2023 or early 2024. We are currently working with three partners: Poseida Therapeutics, PACT Pharma and Fred Hutchinson Cancer Research Center. And we have more pharma partners in the pipeline.

What lessons did you bring from aerospace to life sciences?

Coming from the aerospace industry, where engineering methodology and rigor is much higher than in life sciences, I was surprised by the number of very successful life sciences companies that were built on small incremental innovations. At Cellares, we’re building many different bioprocessing instruments from scratch in a way that is fully integrated in a cohesive system that ties the entire workflow together within one software suite. We’re adhering to a systems engineering methodology, similar to aerospace, to ensure that individual designs are meeting systems requirements, which will result in very high reliability of our technology.

Can you describe the Cell Shuttle?

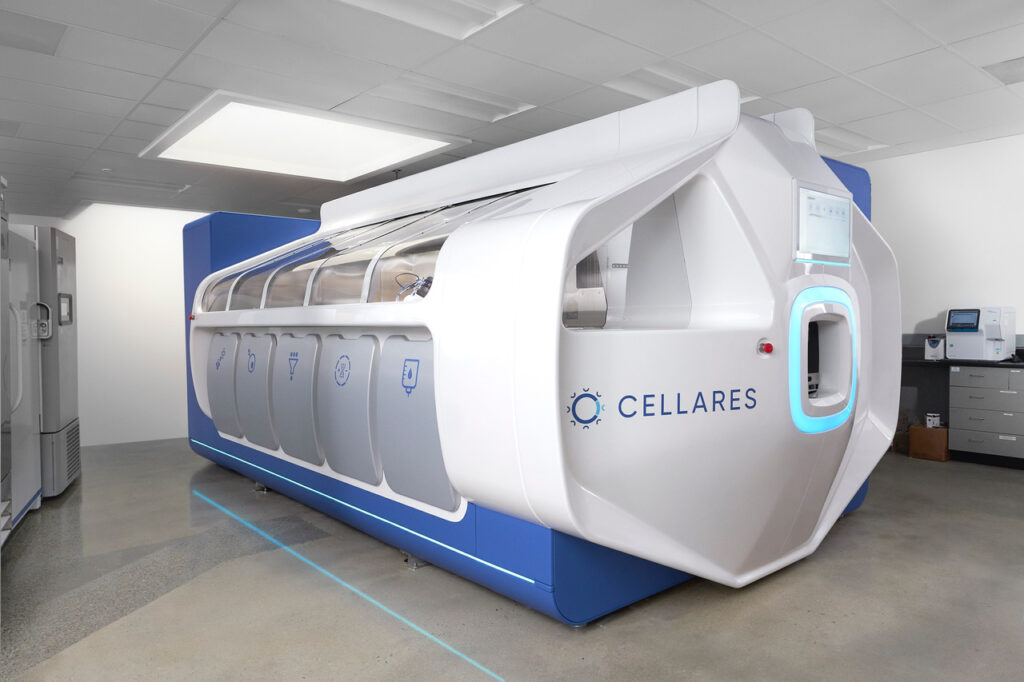

We like to call the Cell Shuttle a factory-in-a-box. The Cell Shuttle is about the size of a small conference room and incorporates consumables, sophisticated instrumentation, and software in a single automated system. Inside, a robot moves a single-use GMP cartridge from one modular bioprocessing instrument to the next one to carry out the workflow that users previously defined in Cellares’ software. This all-in-one closed cartridge mitigates the risk of contamination and process failure, which can happen when operators are using different consumables from different companies for individual steps. Cell Shuttle is designed to support all the processing steps, from loading the starting material to unloading thousands of cell therapy doses a month.

What’s the current state of cell therapy manufacturing?

Cell therapy is personalized medicine that promises to provide cures for devastating diseases, such as cancer. These therapies are often made to order for one patient at a time and require a patient’s or donor’s cells as the starting material. Currently, highly-skilled technicians and scientists spend two-to-three weeks in cleanrooms performing as many as 50 manual steps to make cell therapeutics with disparate benchtop instruments, most of which were never designed for cell therapy manufacturing. Operator error and contamination are the two biggest sources of process failure, and process failure can lead to the loss of a patient’s life. All of the commercially available cell therapies that are FDA-approved today are being manufactured with solutions for one cell therapy manufacturing unit, one patient at a time.

What are the biggest challenges in cell therapy manufacturing?

From our perspective, the biggest challenge is the inability of pharma companies to scale up cell therapy manufacturing at commercial levels to meet demands in the tens or hundreds of thousands of patients per drug per year. The primary reason scaling up cell therapy manufacturing is so difficult is that most are produced in a very manual and labor intensive process one patient dose at a time. This requires pharma companies to build extremely large facilities to accommodate disparate equipment as well as hire, train and retain operators for all of these separate technologies. This is further exacerbated as manufacturers try to create consistency across multiple sites and countries. All of this contributes to the very high cost of cell therapies today.

How would the Cell Shuttle address those challenges?

In addition to vastly increasing the amount of cell therapy doses that we can potentially produce at one time, the Cell Shuttle’s fully automated and closed end-to-end manufacturing solution would enable our pharma customers to run the exact processes specified for their cell therapy. Compared with currently available cell therapy manufacturing, our next-generation platform would enable a three-fold reduction in process failure rates and be capable of producing more than 10 patient doses in parallel, which increases manufacturing scalability by an order of magnitude. We are reducing the amount of human labor required by up to 75% and the amount of GMP clean room space that’s required by up to 80%. We believe these improvements would reduce the per-patient manufacturing cost by up to 70% for most processes.

How important is flexibility in Cellares’ cell manufacturing?

In cell therapy, the process is the product and flexibility shouldn’t be compromised for automation. We believe any automated cell therapy manufacturing technology must offer the flexibility to support a wide variety of different manufacturing processes. One of the most differentiating factors of Cellares’ manufacturing solution is that it combines automated modular hardware with a software suite that enables users to run and optimize precisely the process that defines their manufacturing process.

What benefits have you gained from your Early Access Partnership Program?

We are taking a very open and collaborative approach with our partners. As part of our partnership program, our partners are giving us insight into their manufacturing processesand unit operations which enables our scientist and engineers to build a manufacturing solution that perfectly meets their needs. It also puts us in a position to gain strategic insights into a wide variety of different types of cell therapy manufacturing modalities, such as chimeric antigen receptor-T cells, the first cell-based gene therapy approved by the FDA; autologous and allogeneic stem cells; and T-cell receptor cells.

What has the industry reaction been to date?

It has been very favorable. We’re having a lot of traction with pharma companies; more conversations on the business development side than I care to count. In addition, we’ve generated a lot of data on our internal prototypes already that demonstrates we can execute every single cell manufacturing unit operation with high quality. That’s where my confidence comes from. We know we can uniquely solve a high value problem for this industry.

Where do you expect to be in five years?

We expect Cellares to be the market leading cell manufacturing technology in five years. I think we will have seen a lot of adoption and will be on track to be the de facto standard for automated, highly-robust, scalable and cost-effective cell therapy manufacturing.

• • • • •

To connect with Cellares or any of the other companies featured on BioTuesdays, send us an email at [email protected].