As vice-president of business development for Bay Area Research Logistics (BARL), a specialized clinical trial design, packaging and logistics firm, Nicole Grannell manages the logistical components of multinational clinical trials, both in developed and emerging markets. Ms. Grannell began her sales and marketing career with Big Pharma in Canada, specifically Wyeth and Boehringer Ingelheim. At Wyeth, she began working in sales before being promoted to senior product manager for Alesse (an oral contraceptive) and Effexor XR (then the top selling anti-depressant in Canada). Her career then took her into sales management. Working in pharmaceutical sales and marketing led to an interest – and the development of skills – in the clinical trial aspect of drug development and approval. In this interview with BioTuesdays.com, Ms. Grannell discusses the logistics component of clinical trials and BARL’s service offerings.

Let’s start with a brief history of BARL.

The company was incorporated in 2007. When I joined BARL, it had an operational focus but needed to incorporate business development to ensure steady growth. BARL is a subsidiary of Bay Area Health Trust, an independent business associated with Hamilton Health Sciences and McMaster University. BARL was originally established to meet the research logistics needs of the David Bradley Research Institute in Hamilton. Researchers there wanted a specialized packaging and logistics company to handle all of their requirements – from protocol design to ensuring the trial was performed to the correct standards and, most importantly, that the work was done on time. World-renowned cardiologist Dr. Salim Yusuf, in conjunction with Gita Sobhi, a hospital clinical trial pharmacist, approached Bay Area Health Trust and initiated a process to establish BARL as a separate operating division. The first trial was a study sponsored by Astra Zeneca, with Dr. Yusuf as the principal investigator. Known as HOPE III, the Phase 4 trial enrolled some 12,000 patients at more than 52 sites in eight countries.

How best would you describe what BARL actually does?

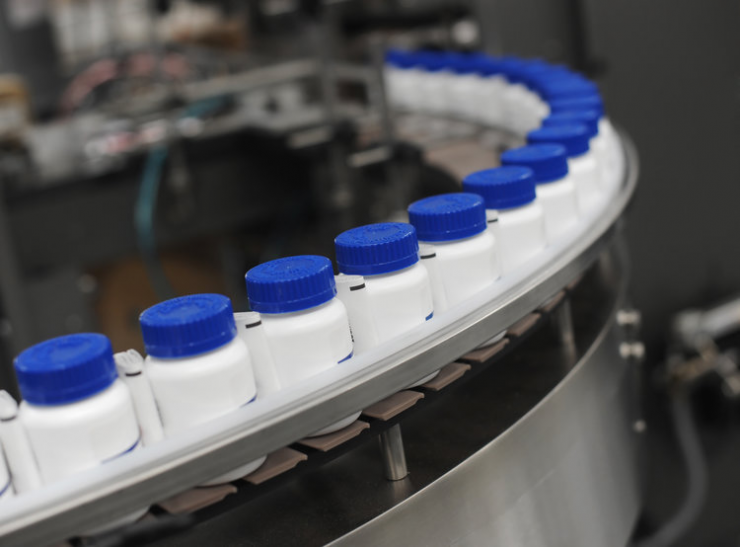

As a GMP facility, we fall into the category of CTMS, or clinical trial materials supply. We take bulk drugs and bottle, label and kit them for distribution to trial sites for use by participating patients. Since we ship to more than 25 countries, we implement and manage very specific packaging plans and import logistics. Companies need to know their logistics team has the knowledge and expertise for a trial drug to be appropriately packaged and delivered to a trial site, and that the required time frames will be met. This helps to facilitate patient enrollment. We often act as the co-ordination team for our clients. We can also manage procurement of a comparator drug and matching placebo, and we can collaborate with a contract research organization (CRO), if necessary.

Packaged drugs for clinical trial use must conform to very specific regulatory requirements. If not done correctly or, most importantly, on time, the entire trial and clinical program can be delayed.

Why is packaging so important?

Packaged drugs for clinical trial use must conform to very specific regulatory requirements. If the packaging is not done correctly or, most importantly, on time, the entire trial and clinical program can be delayed. There are many ways to approach a packaging plan. While it is imperative to maintain the blinding of a clinical trial, packaging design can have a significant impact on costs and implementation at the trial sites. Many logistical considerations must be taken into account to prevent unblinding during a trial. These can include paperwork that accompanies the shipments to each site, the content on labels, the continuity between batches and the timing on packaging. A logistics team must carefully develop and implement a plan to ensure problems do not arise during a trial, and that any changes required are quickly implemented.

Why don’t CROs do this?

CROs don’t actually handle drugs. They work on the clinical components of a trial, and not the materials components. We haven’t found any CROs that combine drug packaging with clinical trial management.

What makes BARL different from other packaging suppliers?

Our business design is intentionally different. We design and print clinical trial labels in house, so this important function remains under our control. We do not package or distribute commercial drugs. Other packaging companies focus on commercial drugs as their main business and clinical trial packaging as a subset. We can be flexible and responsive to our clients’ changing needs. Clinical trials rarely run smoothly, and we are structured to take this into account. In an emergency, when a client needs replacement kits, we can deliver them on the same day, without cutting corners on quality. We have designed our organization to be nimble and to accommodate special requests.

Tell me about the team at BARL.

The team members at BARL all have backgrounds in health care. Our quality assurance/quality control manager is a hospital clinical trial pharmacist, with experience not only in the services BARL offers but also in running on-site clinical trials. She is invaluable in helping client teams understand how the actual trial site will be using a drug and dispensing it to patients. This helps in the design of both the primary and secondary packaging, as well as the logistics of getting the drug to the site. We have very little staff turnover and our project managers are fully trained and have pharmacy experience. Even our packaging and shipping teams have health care backgrounds and understand the complexities involved in ensuring accuracy when it comes to sending the right drug to the right place, and the impact of this on a trial and participating patients. We understand that even a label that is a bit smudged and difficult to read can present a problem in a clinical trial.

Where do you think the business is going?

BARL recently signed a contract for a large trial at Mount Sinai Hospital in New York to bottle, label and assemble kits, and to store and distribute the drugs.

There is a tremendous growth opportunity for BARL. Within the Canadian market, we have doubled our trial volume over the past year. And over the past six months, academic CROs, as well as biotech and pharma companies in the U.S., have contacted us and we have initiated trial projects for them. We fill a niche as a specialized partner, that’s responsive to a client’s needs, and can execute both small and large packaging runs quickly, accurately and within tight deadlines.

Can you elaborate on any of your U.S. contracts?

We recently signed a contract for a large trial at Mount Sinai Hospital in New York. The hospital chose us in a competitive bidding process. Under the contract we are bottling, labeling, assembling kits, storing and distributing drugs. We are also procuring the comparator drug and the placebo on behalf of the trial sponsor. This is a global Phase 4 trial of a marketed drug.

What’s next for BARL?

To date, we have emphasized work in the Canadian market, although we have been involved in some significant Phase 4 U.S. trial work. We are now focusing our efforts for growth in the U.S. We have sales teams on the ground and are increasing our overall presence there. BARL is a perfect fit for smaller, start-up biotech and pharma companies – based on our ability to provide expertise, manpower and flexible schedules to help get drug candidates accurately and quickly through the clinical trial program, and ultimately to market.