As president and CEO of closely-held Blue Spark Technologies and co-inventor of its newest product, TempTraq, John Gannon’s career has stretched from the aerospace industry to Wall Street, culminating in 2011 with this developer of thin, flexible printed batteries built on IP from Eveready Battery, now Energizer. He has worked as an engineer in GE’s Astro-Space division and in currency derivatives with Merrill Lynch in New York and Barclays Capital in London, drawing on his background in mathematics, physics, engineering and business administration. In this interview with BioTuesdays, Mr. Gannon discusses Blue Sparks’ TempTraq medical device, a wireless, wearable patch that continuously monitors body temperature for the hospital and home markets.

Let’s begin with a brief history of your company.

The company was formed in 2003 as Thin Battery Technologies to develop thin, flexible printed batteries built on IP licensed from Eveready Battery, which is now Energizer. In the first few years, we were successful in putting high volume manufacturing in place to commercialize this revolutionary technology. Since 2004, over 300,000 of our thin, printed batteries have been produced and delivered. We then turned our focus to developing applications that required thin, flexible power, were comfortable to wear and could collect data, resulting in our flagship product, TempTraq, which was FDA-cleared as a Class 2 medical device in 2015. And our focus going forward is on wearable medical devices, which can use our technology as a power source.

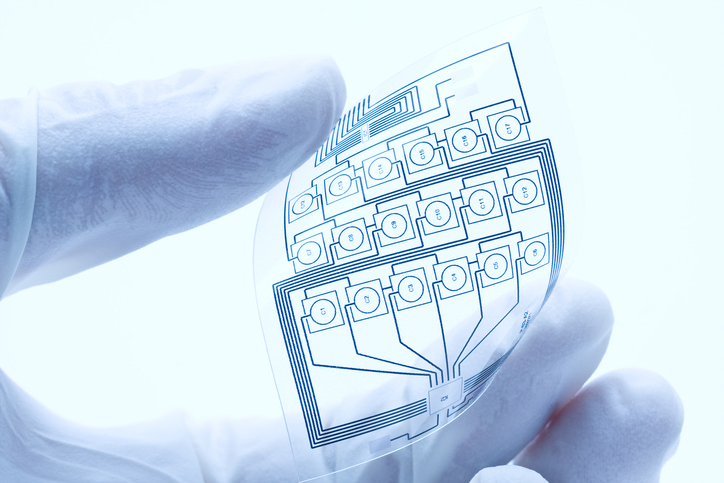

According to Gannon, newly developed electronic inks are used to print active devices, such as thin film transistors and thin printed batteries

Can you explain the term, printed electronics?

Printed electronics is the term used for a relatively new technology that defines the printing of electronic circuits and components on common media such as paper, plastic, and textile, using standard graphic arts printing processes and press equipment. Newly developed electronic inks are used to print active devices, such as thin film transistors and thin printed batteries. Leading-edge companies are currently using the technology to transform basic circuit elements, such as thin-film transistors, resistors, inductors, and capacitors into printed batteries, displays, sensors, radio-frequency identification (RFID) tags, interactive packaging, solar panels, and even speakers.

What are the advantages of printed electronics?

Some of the advantages are their low cost, and ease of production and integration. In many industries, printed electronics technology is expected to facilitate widespread development of functional electronic devices that can be useful for applications not typically associated with traditional electronics, such as flexible displays, smart labels, animated posters, novelty items and active clothing.

Can you describe how this dovetails with TempTraq?

Temptraq is a wearable patch consists of a temperature sensor, microprocessor, communication module, with a thin, flexible battery

Our wearable patch consists of a temperature sensor, microprocessor, communication module, with a thin, flexible battery, all contained in safe, biocompatible adhesives and foams. The device can take temperature readings, store the reading and then, using low energy Bluetooth technology, communicate the reading out 50 feet to either a gateway capture device or a smart phone or tablet.

Why is continuous temperature monitoring important?

When we talk to clinicians about overall biometric monitoring, they say temperature is one of the most important vital signs where there hasn’t been any significant evolution in measurement during the past century. The standard of care is single point readings every four-to-six hours, which are manually entered to a patient’s chart. Compare that with finger clips for continuous oxygen readings and continuous readings of blood pressure. We think continuous monitoring of temperature is a trend whose time has come.

How does TempTraq work in the clinical setting?

The device has a unique identifier on each patch, which is important in the clinical setting because it allows data from a specific patch to align with a patient identifier number. Using our TempTraq Connect, which is a secure, HIPAA-compliant service and supported by Google Healthcare Cloud Platform, our 72-hour disposable patches can integrate directly with hospital central monitoring and electronic health records systems to safely and securely store patient data. The value proposition in hospitals is that by identifying fever earlier, clinicians can intervene faster, leading to better patient care.

According to Gannon, in terms of the consumer market, the focus has been parents with children under the age of 12

How does TempTraq work in the home market?

In the consumer market, our focus has been parents with children under the age of 12. TempTraq currently is being sold in about 15,000 stores nationwide for the home market. An app for an iPhone or Android smart phone receives continuous monitoring of temperature of sick children, adding peace of mind about whether a fever is worsening or improving. The advantage is that you don’t have to wake up a child to get that answer.

Is there any clinical data you can discuss?

A recent study by University Hospitals Seidman Cancer Center in Cleveland found that the TempTraq patch detected a rise in body temperature up to 180 minutes earlier, in a majority of patient cases, than current standard of care. To study this continuous, real-time method of body temperature measurement, UH tested the feasibility of monitoring body temperature for patients specifically undergoing stem cell transplant or intensive chemotherapy for leukemia. The patches were applied every 24 hours on 10 neutropenic patients throughout their hospital stays. Body temperature was recorded remotely with TempTraq in 10-minute intervals, resulting in more than 14,000 temperature measurements, compared with the current standard standard-of-care of one measurement every four hours. The study results were published in the Journal of Clinical Oncology in May.

How do you see TempTraq transforming healthcare going forward?

Post-op, a major expense in hospitals is managing patients with sepsis so identifying fever as early as possible can be critically important. TempTraq also has a role in the ER during patient admissions and in intensive care wards. Hospitals are very interested in outpatient monitoring after they send a patient home, with data sent back to a doctor or central nurses’ station.

What’s in your pipeline?

In addition to the 24-hour patch we are already offering to consumers, we’re preparing to introduce a 48-hour patch for the home market, along with our HIPAA-compliant TempTraq Connect platform. In addition, we are looking to integrate additional sensor capabilities in the platform, a project we will begin in the second half this year. Our current primary focus is wide scale hospital implementation of TempTraq. We view TempTraq as a product that can be used throughout a hospital.